WEG Overload Relays - Wistex, LLC

Guaranteed Safety for your Equipment!

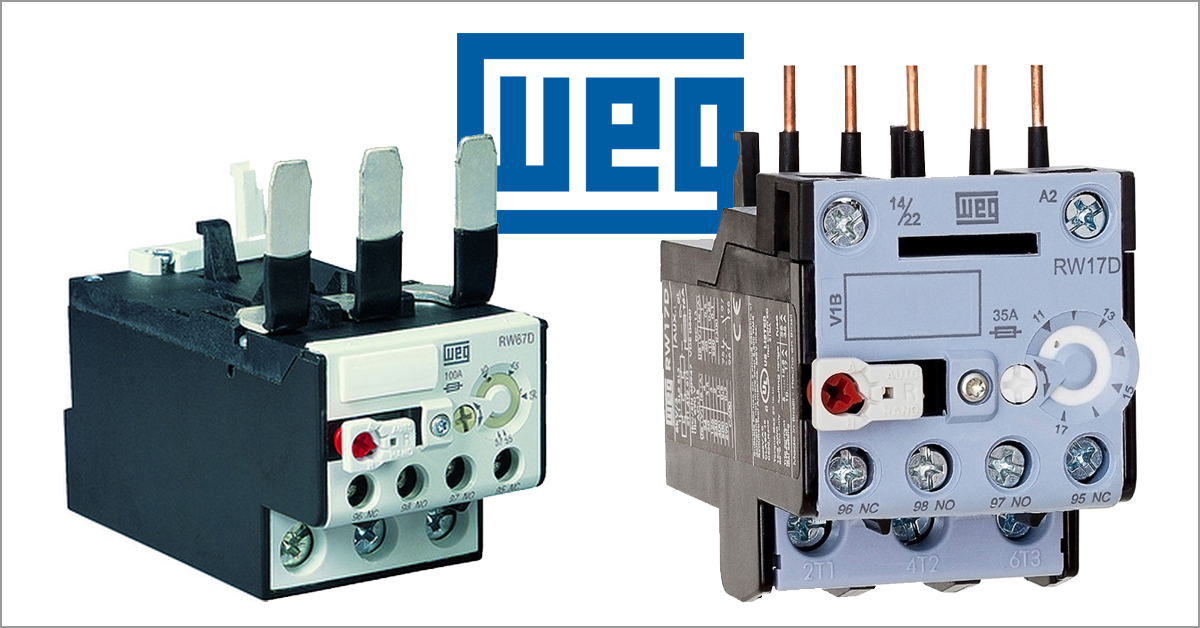

WEG overload relays are designed to ensure increased reliability in protecting low voltage single-phase and three-phase electric motors in networks with 50/60 Hz frequencies where ease of maintenance, reliability, and low power dissipation are mandatory.

The solid-state overload relays are manufactured with cutting-edge technology under the most stringent standards worldwide, such as UL 60947-4-1A (UL 508) and IEC 60947-4-1, and produced with environmentally-friendly and recyclable materials.

The WEG overload relays protect a wide range of loads against overheating caused by phase loss or overloads. Since an overload or a phase loss in a circuit can significantly increase motor current, WEG overload relays are designed to detect such current increases and activate the tripping mechanism that then actuates on the auxiliary contacts 97-98 (NO) and 95-96 (NC).

As a result, the auxiliary contacts isolate the load via a contactor. The duration for disconnection is related to the current setting on the relay as well as the overload current. After the trip, it is important to wait for the system to stabilize before doing the reset, which can be configured automatically or manually.

Main Characteristics of WEG Overload Relays

WEG overload relays are available in both three-pole and two-pole versions. The relays count on two independent and extremely reliable built-in auxiliary contacts (12 V, 10 mA). When properly wired in series with the contactor coil, the auxiliary contacts assure the motor is switched off whenever a failure occurs, but it can also be used for system monitoring purposes.

On the front side, the relay features a RESET pushbutton and a TEST switch, which both function to allow checking proper wiring and the auxiliary contact’s status. The front side also contains a status window (TRIP) that shows the current operation status of the relay.

WEG Solid-State Vs Thermal (Bimetallic) Overload Relays

Traditional thermal overload relays are designed to imitate the heat actually produced in the motor. They effectively simulate the motor heating by passing the motor current through bimetal strips, either directly or indirectly. As the motor temperature rises, the temperature of the thermal unit of the relay similarly rises. The generated heat then bends the bimetal strips and, based on the current setting of the relay, activates the trip mechanism.

In most normal applications, continuous duty or low number of motor start-ups are common. In such situations, the relationship between motor and relay heating curves is very strong. No matter how high the current taken by the motor is, a thermal overload relay will provide protection without tripping unnecessarily.

However, in intermittent duty applications or frequent motor start-ups, the increase in heating behaves slightly differently in the bimetal strip than in the motor windings, so it’s common to experience undesired early tripping. In such situations, you can rarely utilize the thermal capacity of the motor, and thermal overload relays may not be the most suitable solution.

Flexibility and Versatility of WEG Solid-state Overload Relays

With WEG solid-state overload relays, current transformers are used to measure the motor current, which is then converted into an electronic signal. Unlike thermal overload relays that utilize a significant amount of energy in the bimetal strips, solid-state overload relays exhibit less heat loss in the electronic circuits, which leads to a reduced need for ventilation of cabinets.

Additionally, this technology utilizes micro-processed signals to improve precision and provide better motor overload protection. And that’s not all; WEG solid-state overload relays provide a wide current range with a 5:1 ratio between maximum and minimum settings compared to the usual 1.5:1 ratio with thermal overload relays.

This wide range leads to a tremendously reduced number of relays required to cover all current ranges up to 840 A. In other words, it leads to a great reduction in your inventory and flexibility in planning. The same relay can be used to provide protection for electric motors of different power ratings or for protecting the same motor when applied on networks of varying voltages and frequencies.

Applications of WEG Overload Relays

WEG overload relays are designed to protect both three-phase and single-phase AC motors, as well as DC motors. In applications where WEG overload relays are used in the protection of single-phase AC or DC loads, be sure to follow the wiring diagrams presented by the manufacturer.

Overall, WEG solid-state overload relays are suitable for protecting motors in a wide range of industrial applications, including those where prolonged starting time is required. WEG relays can effectively protect motors on low, medium, or heavy-duty applications by simply selecting the proper trip class (such as 10, 20, or 30 as per the IEC 60947-4-1 requirements) in the DIP-switches.

Additionally, the micro-processed electronic circuits of WEG overload relays are temperature compensated, which means that the tripping point remains steady in the entire temperature range of between -20 °C and +60 °C, and it performs consistently without unnecessary tripping.

Get Quality WEG Overload Relays from Wistex LLC!

Wistex is your trusted electrical distributorship and service company specializing in variable speed drives and controls. What sets us apart from our competitors is our in-depth product knowledge and superior customer support. Over the years, we have built solid relationships with well-known, established, top-of-the-line product manufacturers, so we can offer great pricing and solutions that provide money-saving opportunities. We also offer free 24/7 tech support on the phone. If needed, we can send someone out to help at a competitive fee. Contact us today to make your order!